We had a customer email recently here at Ionic Industries. During battery replacement on their Type 3728 Braun Oral-B toothbrush the customer had broken a couple of the copper wires from the charging coil where they connect to the PCB. Using the Type 3728 toothbrush we have for testing we were able to identify the connections for the 4 coil wires and quickly write some instructions for repairing the wiring connections. See below for a copy of the instructions we sent!

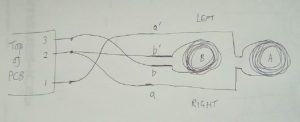

Take a look at the photo and hand-drawn sketch of the wiring connections above. You see in the photo where the four copper wires go into the white cap containing the coils of wire? Two wires go in and turn left. The other two go in and turn right.

Let’s call the two that turn left a’ and b’ (a-dash and b-dash). We’ll call the two that turn right a and b

With all four wires disconnected from the PCB you can use a continuity meter to identify the wires and label them using some tiny strips of masking tape or similar:

- Wire a and wire a’ are the same wire wound into a coil. Let’s call that coil A.

- Wire b and wire b’ are the same wire wound into a coil (coil B) in the same direction as coil A but not electrically connected to coil A.

- Pick one of the wires that turns right. Let’s label that as wire a

- Using the continuity meter find wire a’ because you should get continuity between a and a’. Label wire a’

- The other wire that turns right is b so label it it as wire b

- You should also get continuity between b and b’. Label wire b’

It’s important that both a and b are the wires that turn right in the cap.

Now look at the photo again and the PCB with the 3 pins that the copper wires connect to. Let’s label the PCB pins left to right with numbers 1, 2 and 3.

The wires are connected to the PCB as follows:

- PCB pin 1 – wire a’

- PCB pin 2 – wire a AND wire b’

- PCB pin 3 – wire b

Solder the correct wires back onto each PCB pin and your brush should charge correctly again. To get a good solder connection you might need to scrape the clear insulation off the wires or melt it off using the soldering iron.

Has this helped you? Have you tried it on the Type 4729 or others? Please leave a comment below!

Also see our complete guide to replacing the battery in the Braun Oral-B Type 3728 toothbrush.

In the process of replacing the battery on a Braun 4729, one of the charging coil wires has broken off at the point where the wire leaves the charging coil housing. How do I unwind enough wire from the coil to reconnect it? Are the wires glued to the housing?

Many thanks

Richard Bush

Hi Richard, if you can’t rejoin the wire you should be able to unwind one turn of wire from the coil to give you enough slack to solder the wire back to the PCB. There might be a blob of glue holding the wires down but if this is “hot glue” you might be able to peel the glue off. Be very careful not to break the other wires though! Let us know how you get on 🙂

I have just fixed my Braun Oral B with exactly this problem. With a big magnifying glass it was possible to see the loose wire on pin 3 . Its a difficult solder but with careful hands you can save a bundle. This was caused by falling off the bathroom shelf into the sink. Be careful when removing the brush head collar and be careful opening the unit using the charger as a spanner.

Great picture saved my bacon two wires broke and wasn’t sure which was which

Not very easy to solder but sorted in the end with magnifier

Glad it was helpful Delboy!

Hi, many thanks for your drawing. I was in the same situation as Richard above (with a 4729). One of the coil wires got broken and unfortunately it was wire a’ from the coil underneath so I couldn’t unwind just a little bit because the wire was stuck by the coil from the b-b’ wire. Therefore I unwinded both wires completely until I could have the slack I wanted on all wires. I winded everything up again, soldered everything back together (not easy for a beginner!), and the amazing thing is: my toothbrush works again! I must say: I fell in love with the thing after all we went through 🙂

Great work – glad the drawing was useful. Let’s hope you and your brush are together for years to come! 🙂

Hi

I’ve got a Triumph v2 brush and after replacing the battery and it would not charge I noticed the coil wires broken from each side, the tooth brush does flash to say the battery is low so that’s good. So I’ve unwound all the coil to slacken enough to the right side and rewound the coil back again and got enough for the left side also and this appears to be making contact with the solder blobs it appears to need to touch but when put on charger I get nothing. Can the coil be unwound and rewound? also it there a way of making sure connections are good with solder on the wire? or hot glue gun?

Thanks in advance and great service you provide.

Hi Jamie, when a coil wire is broken you can unwind a turn of it from the coil and re-solder it to the PCB. If you have rewound the entire coil it shouldn’t make any difference. The main thing is the re-soldering. The wire is coated with a transparent insulating coating which needs to be burned off when soldering. Make sure the tip of your soldering iron comes in contact with the wire when soldering it to the PCB to make sure the clear layer is burnt off.

Quick question: I have a 4735. Is it 4 wires at all times or could there be 3? And by 3, 3 going to the PCB board and not 4? Thank you.

Do you mean a Braun Oral-B Type 4736 toothbrush? On brushes that have 4 wires, two of the wires go to the same PCB pin so there are only 3 PCB pins.

Phew, thanks Ionic, this just saved my $200, 15 year old Braun Oral B Sonic complete, model 4717.

Thank you for your help

Thanks for sharing! I also have broken wires at home.I will look up some people who are knowledgeable about copper wires to help me. However, I’d like to label broken parts in order to prepare everything right before a specialist comes.

I have a Braun Oral B 5000 series toothbrush. During repair attempt one of the 2 plastic clips on the induction coil assembly witch secure the unit to the housing was broken off. Do you know where I could purchase a new coil and the plastic part on which it is wound?

Sadly, spare parts are not available. You might be able to use glue or hot-glue to repair the broken plastic – it doesn’t have to look pretty! The other alternative is to buy a faulty brush off eBay and use the parts from it.

I had broken coil connections on a 3762. In the process of re-wrapping it, I didn’t realize it had kinked. I broke the copper wire well away from both ends. What are my options for fixing or replacing the coil? Could I possibly purchase bulk wire to replace the whole coil? If so, what would be the specs? It appears to have an outer diameter of 0.0130 inches or 0.33 millimeters, which corresponds most closely to AWG 28 solid wire. However, I see above you say the wire has a transparent insulating coating.

Yes the wire has a transparent insulating coating. The wire you use needs to be suitable for use in coils such as transformers or maybe inductors. Sometimes it is known as magnet wire.

I have a grey and Blue Braun 3728 and the charging coil wires broke off but i now know how to fix them. However the plastic base somehow detached itself from the blue area where the actual charger goes in. Any tips on how to re-attach it without having it fall out?

The base cap on the 3728 is in 2 parts that just friction-fit together. Once the whole cap is put back on the brush and the cams engaged by twisting the charger it should all lock together.

My 3765 wires where cut too… can I just unwrap the wire and re-do the coil again with the same wire?

You can use solder to join the broken wire. If necessary you can unwind one loop of wire from the coil. Don’t unwind the whole coil!

Awesome!! did work it is charging again

I have 4729. Recharge is not working. wires were broken. Found out which pair is together. Tried as you described, but not working (little led is not showing charge). Tried many combination, but still not working. Followed instruction; one of each together to 2, and the others to 1 and 3. Not working (led is not lit).

Help?

Is there water damage to the internals of the toothbrush and PCB?

Please help me! Is the same for the type 4717?

Yes, you need to go through the same process of tracing the 4 wires for your Sonic Complete toothbrush. 2 wires go to the middle pin on the PCB.

Is possible to have a video? 😁

Sorry, no video for this. You will have to read through the instructions instead.

ok I’ll try again Thanks

I have a triumph 3762 model I can’ t get it repaired. Like for most of you, I broke the wires during replacing the batteries. I already have tried many time to repair it with the soldering but did not help. I even rewinded both sides of wires and did not help. The brush is charging to full in 24h and then it works for 30sek. Please help 🙁

It could be a problem with the battery or the battery connections rather than with the coil wires.

Thank you for the reply and for giving second life to the brushes. I did not mention that after first repair (replacing battery and connecting coil wires that broke during replacing) the brush was working perfect for a week after a full charge. But unfortunately… after 2 weeks, it fell from a shelf and the coil wires broke again :/ so I soldered them back but it did work only for 30-60sek after a full charge. So I decided to rewind the coil wires from both sides but it did not help 🙁 Do you think I should go for another battery? I really appreciate your help. It is not difficult to buy a new brush but I really would like to get it repaired to avoid electronic garbage waste. Thank you 🙂

Perhaps the fall from the shelf has cracked a solder joint where the battery connects, or has damaged the PCB?

You can also try resetting the battery level meter. See section 6 on our support page here.

Thank you :* I did the resetting battery level meter today and…after the first 10sek of charge, it worked for maybe 40min non stop 🙂 Then again 10sek charging, then worked maybe 4min, and I kept doing it till it was totally empty and then I placed it on the charger for the 24h charging time but unfortunately it stopped charging at all after an hour. So I moved carefully the brush on the charger and the charging came back for maybe an hour and then disappeared again. Now it does not charge at all. And when I press start button, it blings red. I checked the wires connections and everything seems to be ok.

I need to rewind the whole coil: does it matter which winding direction I make? and both (coil A and B) in the same direction, or opposite direction?

The ‘direction’ of the coils depends on how you label the ends and connect them up. Label them so wire a and wire b both turn right as they enter the cap.

Quick question. I accidentaly broke the coil wires while replacing the rechargeable battery pack in our Waterpik WP-900 electric toothbrush. Looks to have only 2 wires, connecting to Coil+ and Coil-. One is still attached to the board, it broke off from the coil end. The other is attached to the coil end and pulled loose from board. Any help on repairing appreciated.

If there are only 2 coil wires they can be reconnected to the board or coil. Just make sure the soldering iron is hot and you burn off some of the clear coating from the copper wire when soldering the wire together where it broke.

In my 4736, I broke 2 of those thin coil wires between 2 & 3 terminals when I replaced the battery. When I looked at the those wires going into the coils, I saw that “a” wire turned right and a’ wire turned left into the coil packs. This is opposite to your drawing. I tested the continuity of the 2 wires still not broken between terminals 1 and 2, and they are from the same coil. So when I solder the 2 broken wire back to the terminals 2 & 3, I should reverse the wire “b” and “b'” in your drawing. Is that correct ?

Left and right are relative and can be reversed as long as you reverse them for both coils A and B. You can cross out the words LEFT and RIGHT on the diagram and swap them over.

Start with the intact wires. Label the two intact wires on your brush according to the diagram so that the direction matches the diagram. You can then work out from the direction of the broken wires how to label those. You can then solder them in place.

Thank you for replying my question. I followed the wiring direction of the intact wires to solder back the two broken wires. Now, the two coil packs are in series. When I tested it out the blue LED came on when I placed the coil into the charging base. I was surprised that the charging voltage (measured at the battery +ve and -ve terminals on PCB) was about 4V instead of less than 3V !

I would like to know what kind of motor is used in the Oral B toothbursh ? I applied about 3V DC to the motor terminals but it did not turn over.

Check that you can turn the motor’s output shaft by hand as it might be seized. Some light oil on the bearings might free it. The motors tend to be welded to the metal chassis of the brush so are not replaceable.

Thank you for the response. I tested the motor again this morning, with about 4V DC applied to motor terminals. Motor did not turn over, then I turned the plastic gear under the motor by finger and the motor ran right up. Motor speed varied with the DC applied voltage down to about 1V (slow speed). However, when I toggled the DC power, motor did not turn by itself. I had to turn the plastic gear by my finger to get the motor running each time. As you stated that motor is welded to the metal case, and the motor shaft was buried inside the plastic gear and bearing. I am not sure that I could put some bearing oil onto the motor shaft. I will try ….

Be careful if applying voltage directly to the motor. Make sure it’s not connected to the PCB as you could damage components. The motor in Ni-MH powered brushes is probably designed and rated for around 1.5V.

Thank you for the head up. PCB was de-soldered a while ago. I applied DC voltage directly to the motor terminals without the PCB.

Received and installed the battery from your store. Toothbrush worked right away, thank you.

Thank you!

Thank you!

Thank you for you instructions and detailed explanations! Even in September 2021 it was very helpful to repair a toothbrush in Germany!

Glad it helped Stefan. Braun continue to use the same charging system in their current Oral B toothbrushes.

Thanks for the explanation and pics.

I just want to say thank you for the great website. This solved my issue.

My approach

How to determine the right connection ?

Measure with an Ohm meter which wire goes with which coil

Put the 2 coils in series (random)

Put the coil on the charger (without the PCB) and measure the voltage of the middle point of the end, this will be 2 times about the same alternating voltage (in my situation 12 Volt)

Then measure the total series voltage. If it is double then it is OK.

If the voltage is near 0 then swap 2 wires.

Check if the voltage is now double.

In my tooth brush 4729 i have broken all 4 coil connections.

You should be able to use a continuity test to pair off the wires into pair A and pair B. Then examine which direction each wire in each pair goes and label them a, a’, b and b’.

Thanks now going to attempt correct procedure. Wish me well and thanks alot for taking your precious time to answer

Should i consider right side of coil by placing coil assembly with charging base down on floor and spring side up or by placing spring side down and coil base side up?

Because i labelled both coils by placing base down on floor and took right side of coil as A and B and connected as oer diagram and now checking if it fully charges battery within 24 hours. I checked voltage of coil by. Connecting in series coils and puttin on charging dock and voltage was 9 volts AC.

The wires that turn right can be defined either with the base facing down or up, but you must be consistent. It sounds like you have got it all connected so that it will work.

Thanks, very helpful.

Following your detailed instructions I reattached the charging coil wires of a beloved 4717 Sonic Complete which now also has your replacement battery. It works well. I needed a magnifier/lights and found the soldering access difficult but luckily just possible for my skill level.

I have a supply of the very rare brush heads if anybody needs one.

Thanks very much.

Oh, my!

Thank you , big thanks!

Just one wire I welded wrong several years ago, the power was not enough to charge it during a day, moreover, it was quickly discharging when off base.

Now it is fantastic, that I founded your instructions!

Both 1- and 3- show 0,1 V with 2+!

THANK YOU, a king of toothbrushes repair :,)

Thank you for the explanation, this helped us in a Repair Café in Bielefeld Germany. One thing that was confusing, is the “turn left and turn right”. This is not related to the way the wires are looped around the base to form the coil but really how they “enter inside the base” and then make a right or left turn before being wrapped around.

All wires were too short (broken close to entering the base), I decided to unwrap the coil to pull one loop more, but the ‘inner=start’ wires require to unwrapp ALL the coil to get one turn off the spool. Rewrapping manually is not as tight/aligned as a machine-wrapped coil and then the coil gets a little too big to reinstert in the base. I had to push/squeeze the top of the coil inside, and this is not ideal. Extending wires, would require to solder and re-isolate the wires with some coating. Probably my next technique to avoid unwrapping.

Thank you for the feedback, and keep up the good work at the Repair Café!

Hello, thank you for the page, diagram and comments! I just opened up my 4731. I see only two copper wires connecting to the PCB. I doubt that is right but wanted to ask. The Green LED no longer lights when charging .

Yes, many toothbrushes only have 2 copper wires coming from the charging coil which is quite normal. It is also easier to repair or re-attach the wires!

If you decide that the battery has failed you might need one of our 56mm x 17mm 2.4V packs which fits some versions of the Type 4731 Oral-B toothbrush.